Skip to contentFeatures & Benefits

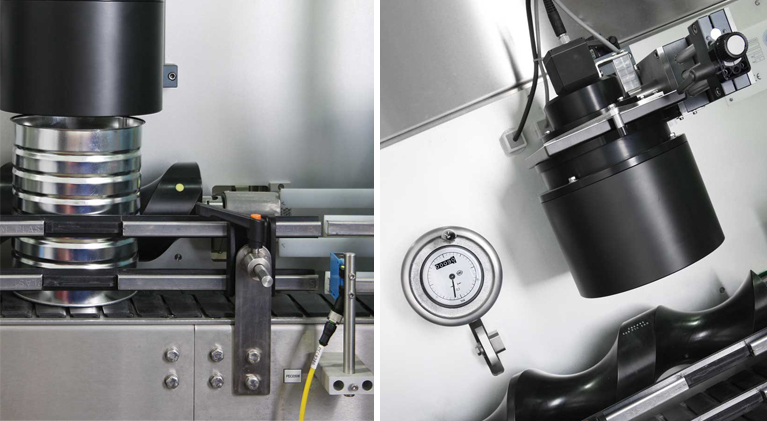

- Particulate detection as small as 2mm for accurate rejection

- Detects and eliminates foreign body contamination from the filling process, ensuring product integrity

- Ensures container integrity and rejects to maintain efficient production

- No lubrication regime required

Details

- Speed up to 300 containers per minute

- Option of automatic position setting for quick container changeover

- Optional embedded Ethernet protocols

- Equal pitching by no tool scroll feed

Options & Models

- Automatic position setting for quick container changeover

- Optional embedded Ethernet protocols